VISOMAX ROBOTICS

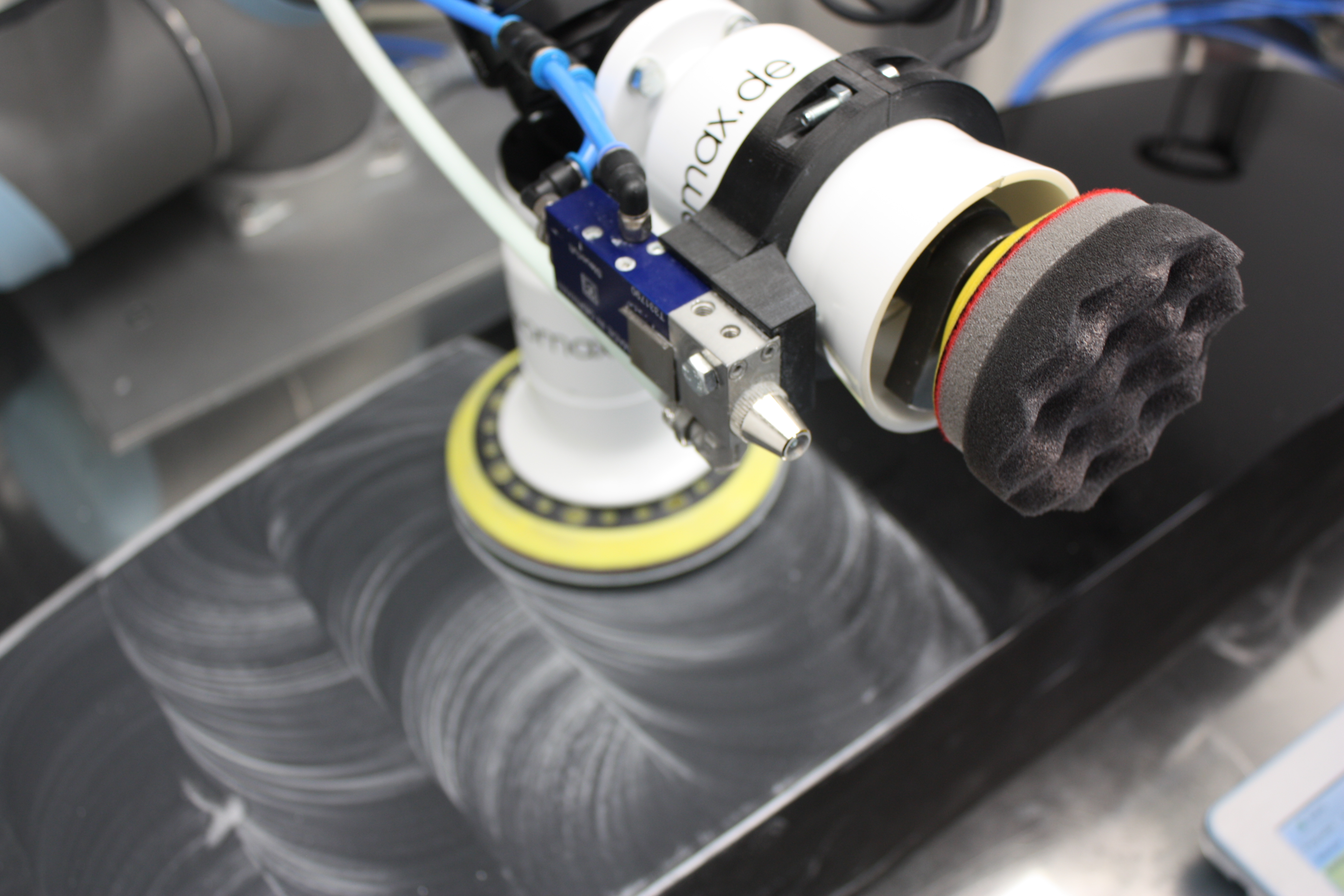

In order to make the finishing process more efficient with increasing batch sizes/quantities, we offer solutions for the automated polishing of surfaces.

The possibilities and variants of the automatic polishing process can be virtually simulated in advance using provided CAD data .

Depending on the geometry and surface conditions, the component is treated over its entire surface by the robot or the defects are detected by a camera system and selectively polished.

VISOBOT

We cannot solve our problems with the same thinking we used when we created them.

Considering the times of elevated volumes, reduced batch sizes and increased product versions the product planning is getting more difficult.

For the production planner an essential parameter is the process time per component which cannot be reproduced in a stable way in a not automated production process.

We recognized this problem and developed a solution for the producers of vehicles and their suppliers.

Simple, safe and efficient.

HIGH / GLOSS

Simple, safe and efficient… one step ahead of our competitors.

Our Visobot including the Y-Tool makes it possible. The surface quality of high-gloss surfaces as in kitchens, furniture and shopfitter elements becomes perfect in an instant. Paint defects as like as dust inclusions and micro scratches got removed by the Visomax Finish System within seconds and residue-free.

This way, today, the high-gloss coating is realized in the furniture sector.